-

PVC Palastik Foam Board Nyieun Mesin

PVC papan foamed milik bahan panyalindungan lingkungan anyar.Plat panto dina ukuran normal tanpa ujung, waterproof, Uap-buktina, karasa jeung kalenturan.

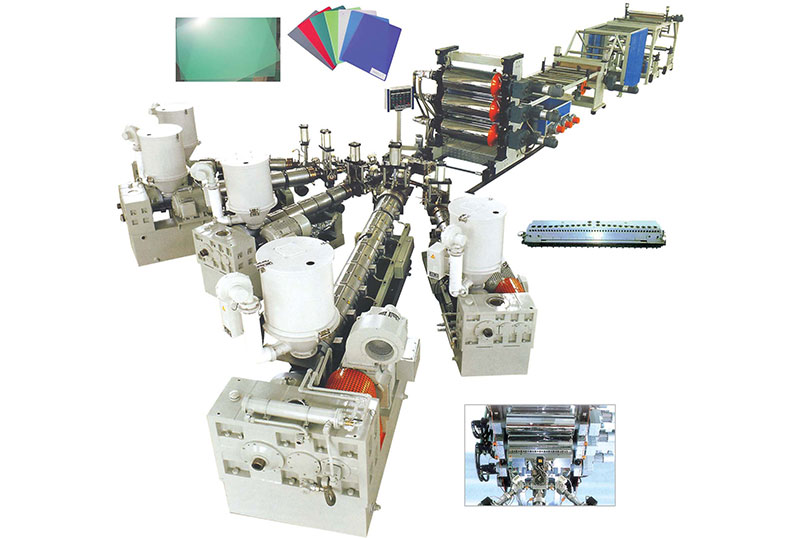

PVC / WPC Foam Board Nyieun Mesin pikeun The Dapur Kabinet, PVC hiasan lambar Board Panel Mesin PVC Foam Board Panel Nyieun Mesin.

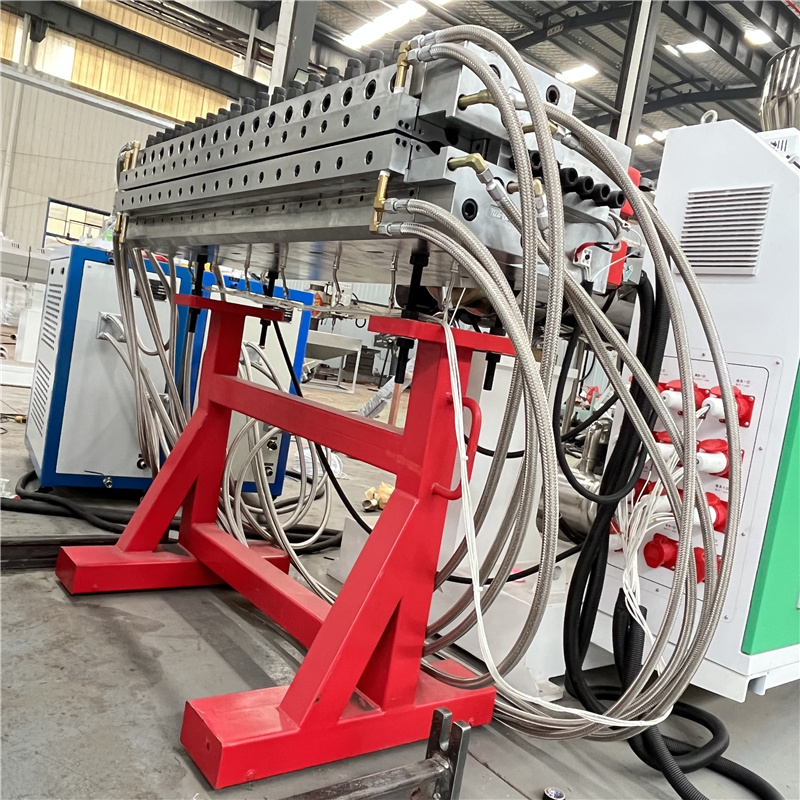

modél extruder: SJSZ80/156,

ketebalan: 2-30mm.width 1220mm,

kapasitas 400-500kg / h,

-

Pvc kerak busa Board Mesin Tonjolan

loba dipaké dina industri konstruksi jeung industri hiasan iklan, Industri hiasan: Indoor jeung outdoor dewan hiasan, rak hiasan komérsial, Industri Transportasi, dewan hiasan interior jeung widang lianna.

WPC Decking Machine, WPC PVC Wood Plastic Foam Board Furniture Board Dapur Kabinet Harga Mesin Board,

Mesin Panel Dekoratif PVC Mesin Panel Panel Dekoratif PVC,

-

WPC PVC kerak busa Board Extrusion Line

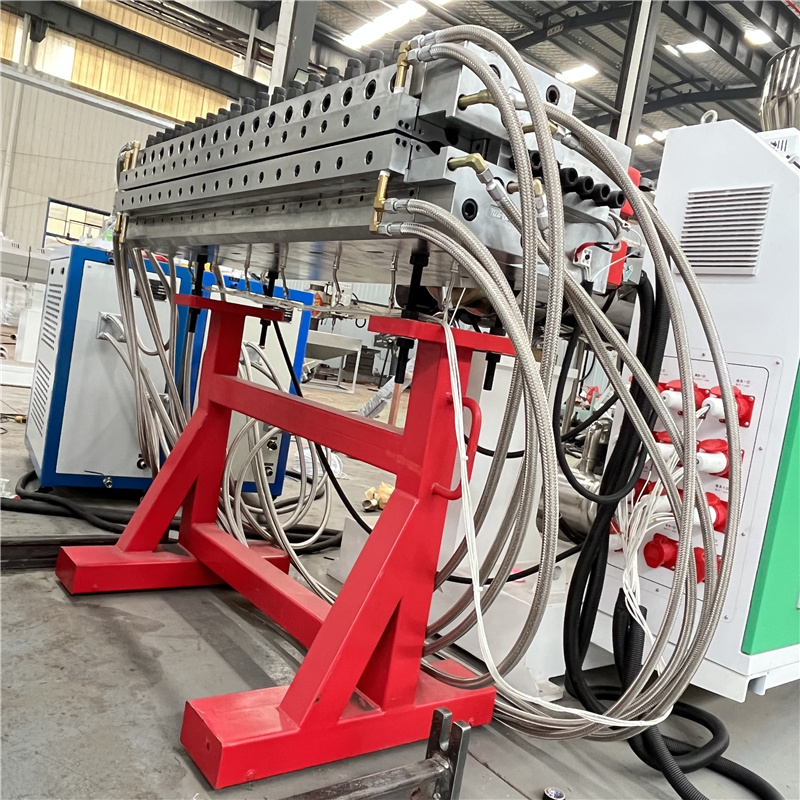

Screw, desain tong sareng manufaktur nyerep téknologi canggih Éropa

Screw jeung tong bahan: 38CrMoAlA, Nitriding dirawat

WPC PVC Crust Foam Board Extrusion Line, Plastik PVC Crust Foam Board Artificial Marmer Stone Sheet Extrusion Production Machine, PVC Crust Foam Board / Plate Production / Extrusion Line Plastic Sheet Making Machine, PVC Wood-Plastic Crust Foam Board Extrusion Machine pikeun Dekorasi.

-

Pvc Dekorasi busa Board Extrusion Line

Pvc Dekorasi busa Board Extruder Line / Busa Board Extruder Mesin ieu Dipaké pikeun nyieun panel konstruksi, panel hiasan, balustrade, trotoar, léngkah, tabel outdoor, panel témbok jeung korsi, pergola, ranjang tangkal, jsb PVC Co-Extrusion Foam Board Line Produksi. Kembar-Screw, Cina Plastik PVC Kerak/Gratis Papan Busa Imitasi jieunan Marmer Batu Lambaran Spc Vinyl Batu Lantai Plastik Lantai Ekstrusi Produksi Produksi Line

-

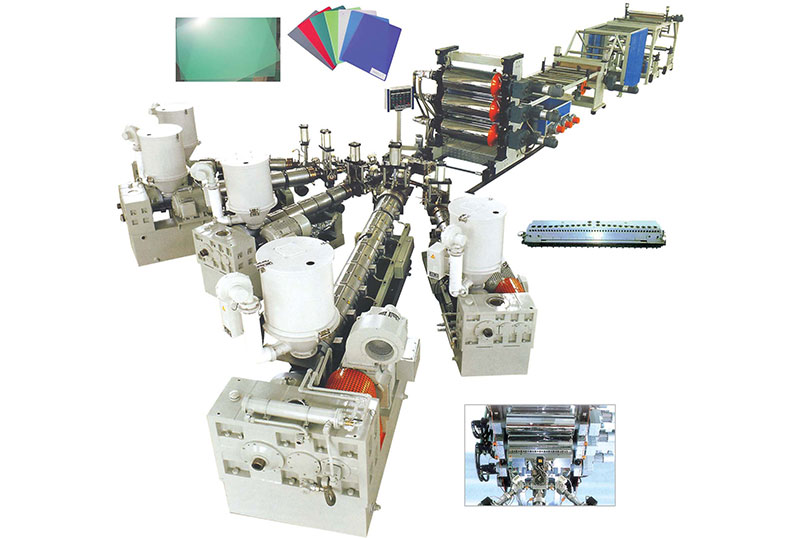

Kaku / Lemes PVC lambar / tiruan dewan marmer Extrusion Line

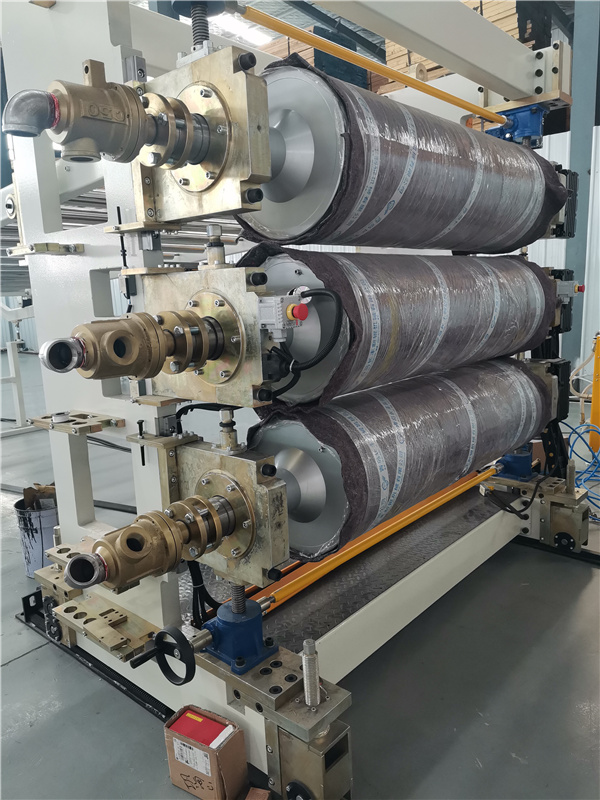

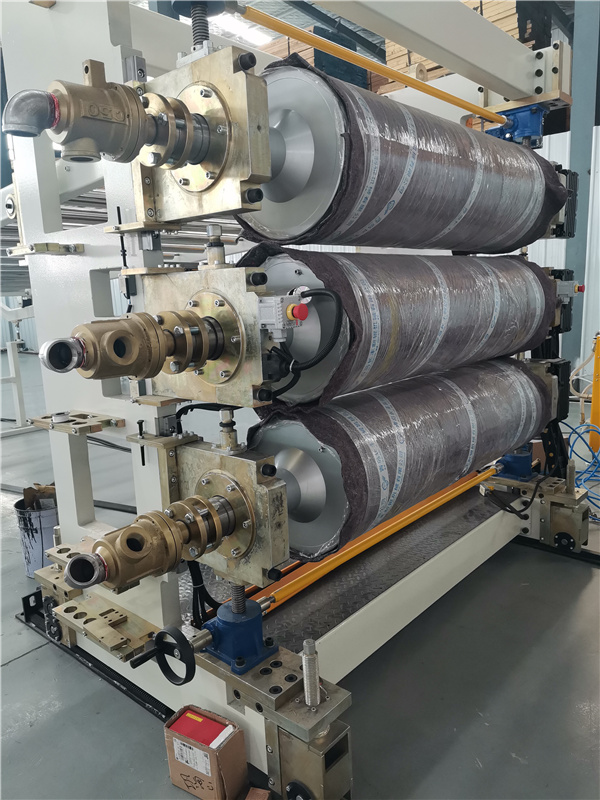

dirancang Kaku PVC cadar garis Tonjolan adopts mixer, kerucut kembar screw extruder, T maot sirah, tilu roller kalénder jeung bagian hilir, kaasup cooling pigura jeung edges trimming, hiasan Unit palapis pilem, Unit korona salaku pilihan, haul off mesin sarta ogé cutter transverse. jeung conveying tabel.

1.kinerja stabil

2.operasi lemes

efisiensi 3.high

4.high-tungtung custom

5. jaminan kualitas

-

Kai jeung Plastik PVC Foam Board Line Produksi

nasabah ogé bisa ngahasilkeun A + B + A tilu lapisan ko-Tonjolan dewan busa ku nambahkeun extruder na distributor mesin .The kedah digitus chiller cai, bisa ningkatkeun efisiensi produksi.

Kualitas luhur PVC kerak Lempeng / WPC Kai Plastik Foam Board Lambaran Tonjolan Produksi Nyieun Mesin pikeun jati hiasan Dapur.

-

Conical Kembar screw palastik Tonjolan Mesin PVC Foam Board Tonjolan Line

Urang specializes di manufaktur PVC WPC mesin busa dewan, mesin lanté WPC, mesin lanté SPC, PVC témbok panel mesin dewan, PVC mesin dewan foaming bébas.Pvc Foam Board Extrusion Line,Profesional PVC WPC Foam Board Extrusion Production Machine Line.

1.kandel dewan 2-30mm

2.kapasitas mesin: 500kg / h

3.lebar dewan: 1220mm

-

PE PP ABS Lambaran dewan Mesin Tonjolan

Plastik PP PS HIPS PET ABS Sheet Extrusion Line Produksi: Jalur produksi ieu diwangun ku extruder palastik screw tunggal, vakum unit dahar otomatis, dehumidifiers drying Hopper, lambar paeh, 3 Unit roller-ray, pemanasan sarta leveling Unit, roll cooling Unit, motong ujung. Unit, traction, Unit shearing, roller conveyor Unit.Kalawan ciri struktur kompak, kinerja punjul, Screw na tong dioptimalkeun design sarta pamakéan-kinerja tinggi alloy 38CrMoAiA processing profésional nu mastikeun yén sakabéh garis produksi seragam palastik leungeun Tonjolan stabil, ngahasilkeun tinggi, hirup panjang tur kaunggulan sejenna.Laras ngagunakeun casting manaskeun manaskeun aluminium, cooling angin jeung alat kontrol hawa éléktronik tepat;ukuran tepat na roller-ray Unit pikeun nyaluyukeun template bentukna alus;Unit motong ngadopsi motong tetep-panjangna pikeun mastikeun panjang akurat.