Pelletizer / mesin daur ulang pelletizing

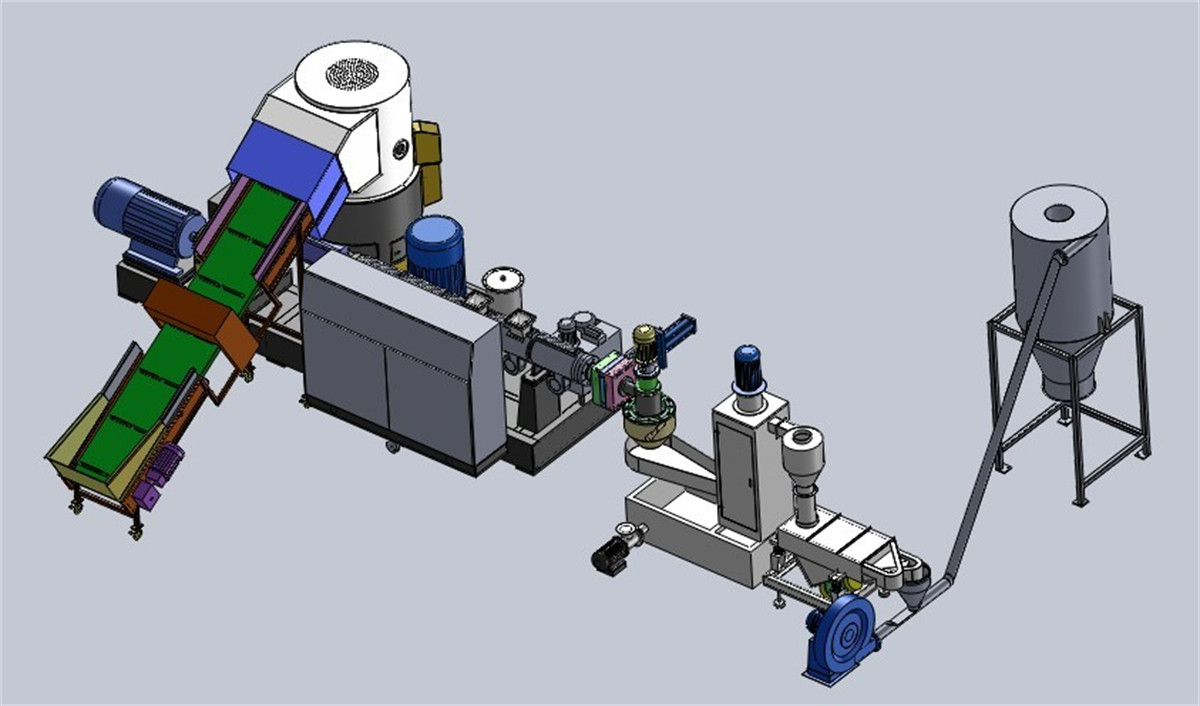

Aliran prosés

Screw feeder (PILIHAN)→ Force feeder→1# Degassing screw extruder →1# Hydraulic filer exchanger→2# screw extruder →2# Hidraulik filer exchanger→ Mould head →Cairing motong →Dewatering machine→ Air dryer Blowing system→ Storage hoper→ Bungkusan produk réngsé.

Urang tiasa ngalakukeun garis Produksi pikeun Granule tina ABS / PC / PP / pe / PVC / WPC nurutkeun bahan jeung kaluaran kami boga desain handap:

PP pe runtah pilem palastik ngadaur mulangkeunana pelletizing mesin garis palastik pilem granulator

Bagan aliran tina garis pelletizing scraps PP / PE

Aliran prosés PP / PE garis pelletizing besi tua nyaéta kieu:

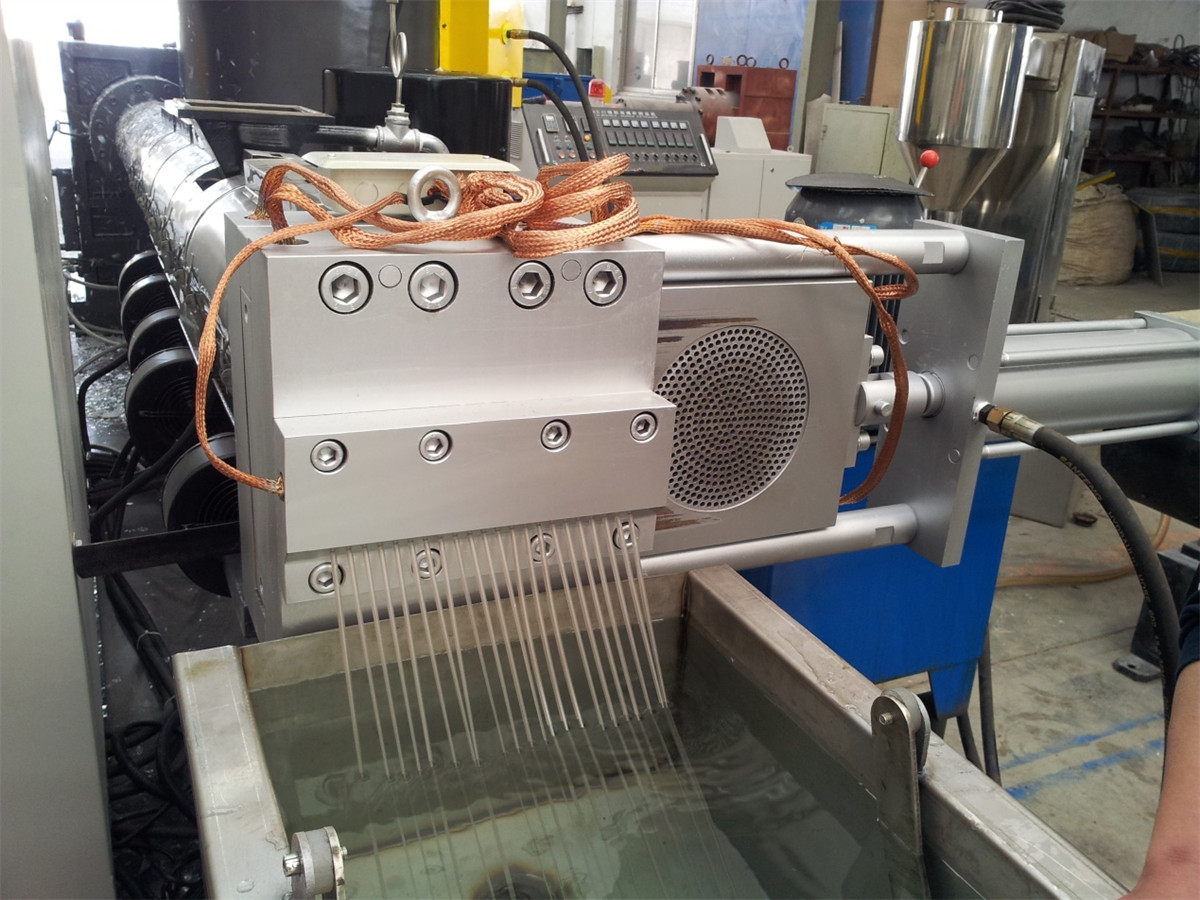

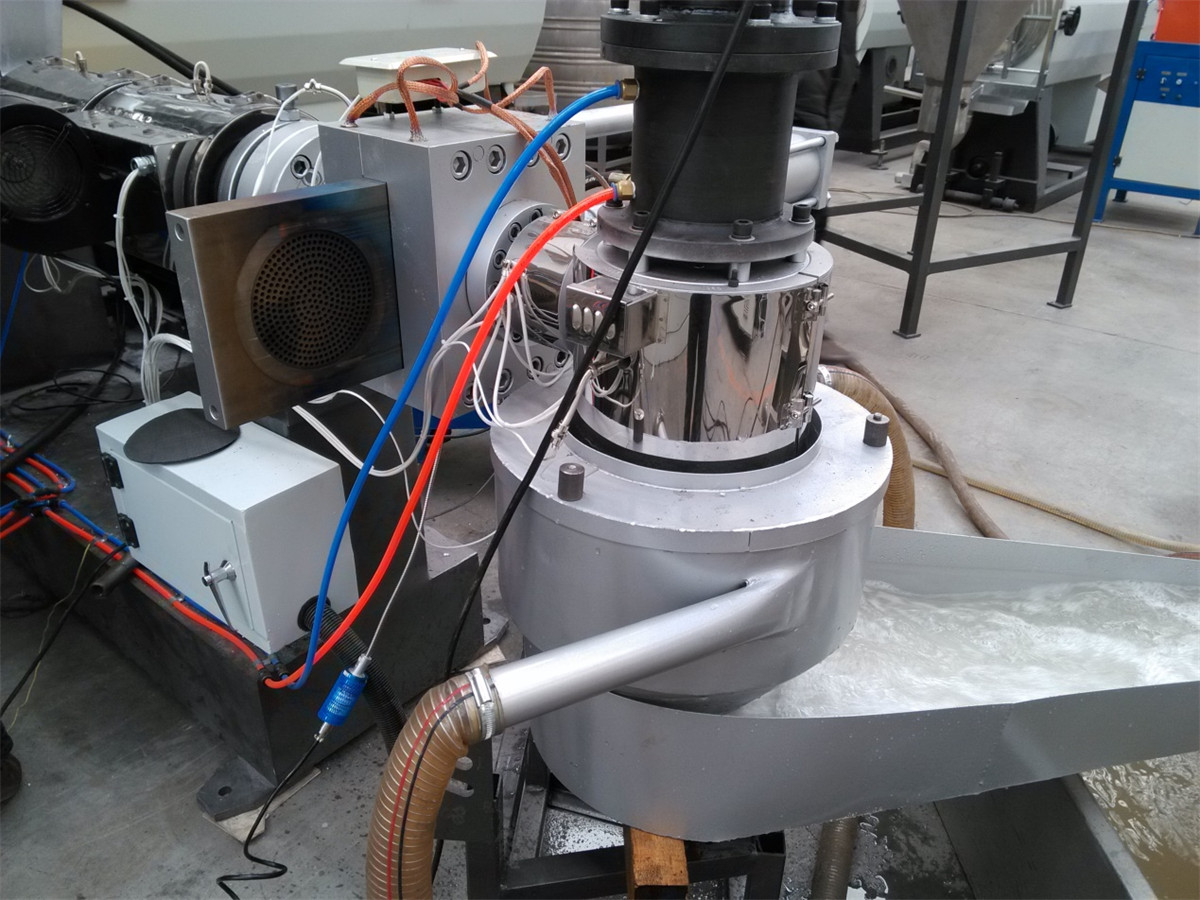

Screw feeder → Sistem Extruding → Sistem bursa Net speed tinggi → mesin pelletizing ring cai → mesin cai troughdewatering sistem blower hawa tabung geter → Panyimpenan

200kg / jam PE / PP scraps garis Pelletizing

Daptar produk

- 1 set tina crusher palastik

- 1 sét feeder blower hawa

- 1 sét feeder screw

- 1 set tina sisi gaya feeder

- 1 set screw nyoco mesin dosing

- 1 susunan SJ100/30 Mesin Extruding

- 1 set tina speed tinggi Sistim bursa Net

- 1 set mesin pelletizing ring cai

- 1 set wadah cai

- 1 sét Mesin dewater

- 1 set ayakan geter

- 1 set sistem blower hawa

Aplikasi

Ganda-tahap reclaimed garis produksi pelletizing teh parabot idéal pikeun pelletizer plastik, hususna keur PP, runtah pilem pe, HDPE, PP, BOPP, HDPE, LDPE, LLDPE, ABS, EPE, EPS, XPS, manteng pilem Non-anyaman fabrics, tas anyaman, bahan padet pulih, recovery bahan ditumbuk na granulation.Garis produksi boga kaunggulan desain novel, struktur lumrah, operasi stabil, noise low, konsumsi kakuatan lemah sareng kaluaran tinggi.